CAT CommuniCATion Adapter (caterpillar Electronic Technician) is an updated version of the dealer level program for the diagnosis of all equipment caterpillar.

This program works with the dealer diagnostic scanner caterpillar Communication Adapter, as well as other adapters for diagnostics including scanner Nexiq; the program provides the full information when troubleshooting.

This diagnostic tool Cat ET 2017C allows service technicians to reprogram ECMs, reconfigure control system parameters, fine-tune performance or diagnose the cause of failure for the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately.

When you purchase a program Cat ET (Cat Electronic Technician) 2017С, you get detailed and clear instructions on how to activate it. But if you have difficulties or questions concerning the installation, we are helping you to enable the software remotely via TeamViewer free of charge, without any additional fees.

We recommend using only Heavy Duty Truck diagnostic Scanner genuine caterpillar comm III

Heavy Duty Diagnostic tools Cat ET diagnostic app allows you to:

View active and logged diagnostics.

View events where irregularities occurred and were logged by the ECM.

View the status of a group of parameters (temperatures, pressures, etc.) simultaneously.

Record and log performance data.

Graph a group of status parameters.

View the current configuration of an ECM.

Change ECM configurations.

Perform diagnostic tests.

Perform calibrations.

Print reports and diagnostic results.

Please keep in mind that some ECM settings, for example, speed limit requires factory password. The factory password generator not included in this application

What’s New – cat Electronic Technician 2017C

Preferences Option to Save a Product Status Report to PDF

The OBD2 vehicle diagnostics Preferences dialog for the Product Status Report has changed. The dialog contains a new checkbox to automatically save a Product Status Report as a PDF file when the report is created. The service tool will continue to automatically save Product Status Reports as an XML file.

CAT Caterpillar ET Diagnostic Tool from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool. The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more. The service tool works with a communication adapter to allow connection to an ECM. A graphical interface makes this software quick to learn and easy to use. A separate pull-down menu for each function enhances the “ease of use.” The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started. Diagnostic tests and calibrations can also be performed.

CAT Caterpillar ET Diagnostic Tool enable service technicians to reprogram ECMs, reconfigure control system parameters, fine tune performance or diagnose the root cause of a failure the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately. The service tool communicates with any system using ATA (J1708), J1939 or the Caterpillar proprietary data link networks. The service tools provide information and features needed to help a technician diagnose problems and perform repairs and to customize and personalize the operation of a product. By allowing customers to design flexibility and configurability into a product, Caterpillar service tools stretch beyond the capabilities of preprogrammed ECMs or onboard display systems.

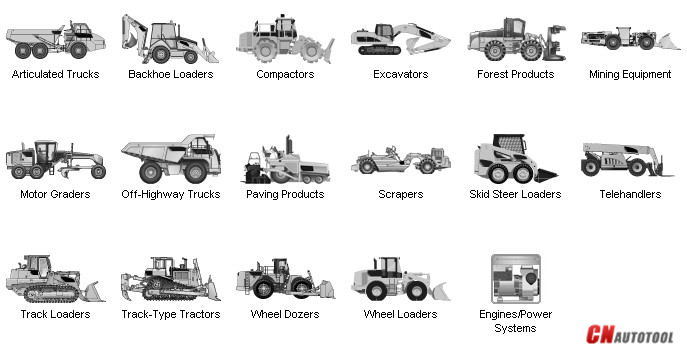

Support car list of CAT Caterpillar ET Diagnostic Tool :

With the CAT Diagnostic Tool, you can:

View active and logged diagnostics

View events where irregularities occurred and were logged by the ECM

View the status of a group of parameters (temperatures, pressures, etc.) simultaneously

Record and log performance data

Graph a group of status parameters

View the current configuration of an ECM

Change ECM configurations

Perform diagnostic tests

Perform calibrations

Print reports and diagnostic results

For some machine and engine products, additional functionality has been included with the service tool program